Welcome to,

Blast Top, Protecting Your Assets.

Protective Coating

Blast Top helps build brand value with use of Advanced Abrasive Blasting Techniques

For Protective Coating.

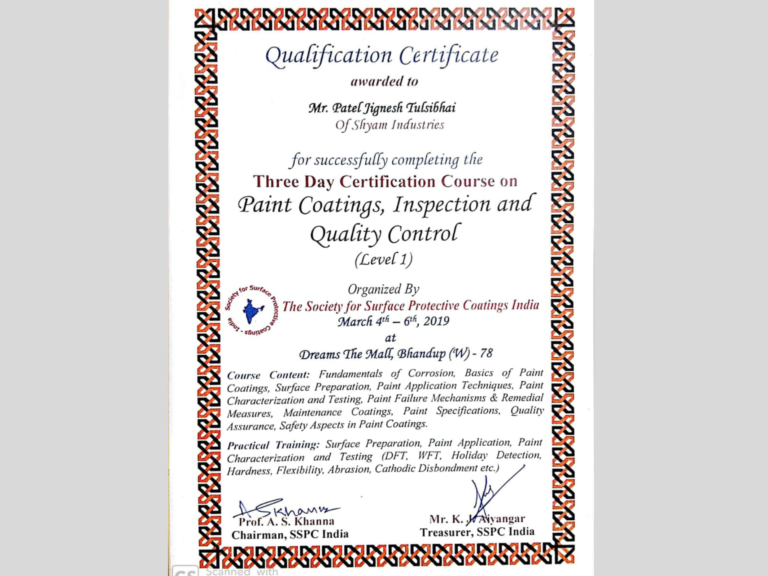

“Blast Top has NACE/SSPC Level 1 & 2 Certified and a highly Experienced professionals Team, which specializes in Stainless Steel and Other Non Ferrous Surface Finishing to deliver top-quality results.”

“Blast Top has NACE/SSPC Level 1 & 2 Certified and a highly Experienced professionals Team, which specializes in Stainless Steel and Other Non Ferrous Surface Finishing to deliver top-quality results.”

What We Offer

Advanced Protective Coating Solutions for Long-Lasting Metal Durability

Your brand stands for quality and durability. Our premium protective coatings and finishes boost product performance, extend lifespan, and strengthen your brand’s value.

Organic Zinc Rich Epoxy Coating

Epoxy Phenolic

Coating

Inorganic Zinc Silicate Coating

Glass Flake Interlining Coating Up to 1500 Mic

Acrylic Poly-urethane Coating (PU)

Epoxy Zinc Phosphate Coating

WHY DO INDUSTRIES NEED THEM?

1. Corrosion Protection

- Provides a durable barrier protecting metal from rust, chemicals, and moisture, preserving the strength and finish of steel and aluminum in any environment.

2. Longer Asset Life

- Extends the life of metal structures and equipment by preventing wear, aging, and degradation, reducing replacements and maximizing long-term performance.

3. Reduced Maintenance & Downtime

- Reduces repairs, repainting, and replacements, cutting maintenance costs and downtime while ensuring smooth, uninterrupted operations.

4. Better Appearance & Branding

- Delivers a smooth, visually appealing finish that hides imperfections and meets brand design needs with various colors, gloss, and textures.

5. Resistance to Chemicals, Heat & Abrasion

- Engineered to resist chemicals, heat, abrasion, and mechanical damage, coatings stay intact in harsh, high-pressure, and industrial environments.

WHY PROTECTIVE COATINGS?

Protecting Surfaces. Extending Lifespan. Reducing Cost.

What Are Protective Coatings?

Protective coatings are applied to metals to prevent corrosion, increase durability, and enhance appearance in harsh conditions.

Why Choose Blast Top for

Protective Coating?

At Blast Top, we are dedicated to providing protective coatings that not only meet but exceed industry standards. Our commitment to quality, innovation, and customer satisfaction ensures that your metal surfaces are protected with the best coatings available. Whether you need a coating for industrial machinery, architectural elements, or high-performance components, we have the expertise and technology to deliver superior results.

For Boost Your Brand Value with Our Expert Metal Surface Solutions — From Preparation to Protective Coatings.

Are You Ready

Our Applications

- Aircraft Manufacturers

- Airport

- Automobile Industries

- Auto-Truck Body Builders

- Chemical Plant

- Drug & Pharma Industries

- Food & Dairy Industries

- Holloware Industries

- Pharma machinery Mfg

- Jet Turbine Blade

- Manufacturers

- Machine shop & Engineering

- Plastic machinery

- manufacturers

- Power Station

- Pulp & Paper Mill

- Rubber Plant

- Stamping Plants

- Ship Building

- Surface Cleaning

Why Choose Blast Top for

Protective Coating?

At Blast Top, we are dedicated to providing protective coatings that not only meet but exceed industry standards. Our commitment to quality, innovation, and customer satisfaction ensures that your metal surfaces are protected with the best coatings available. Whether you need a coating for industrial machinery, architectural elements, or high-performance components, we have the expertise and technology to deliver superior results.

For Boost Your Brand Value with Our Expert Metal Surface Solutions — From Preparation to Protective Coatings.

Are You Ready

What We Offer

Advanced Protective Coating Solutions for Long-Lasting Metal Durability

We understand that your brand’s reputation is built on quality, durability, and excellence. Protective coatings & Special Finish not only enhance the performance and longevity of your products but also play a crucial role in reinforcing your brand’s value. Here’s how our top-tier protective coatings & Finishing can make a significant impact:

Organic Zinc Rich Epoxy Coating

Epoxy Phenolic

Coating

Inorganic Zinc Silicate Coating

Glass Flake Interlining Coating Up to 1500 Mic

Acrylic Poly-urethane Coating (PU)

Epoxy Zinc Phosphate Coating

WHY DO INDUSTRIES NEED THEM?

1. Corrosion Protection

Acts as a long-lasting physical and chemical barrier that shields metal surfaces from rust, oxidation, and other forms of corrosion caused by environmental exposure.

Effectively protects against moisture, salt spray, industrial chemicals, and pollutants that accelerate metal degradation.

Maintains the structural integrity and surface quality of steel and aluminum in both indoor and outdoor environments.

2. Longer Asset Life

Increases the usable lifespan of equipment, machinery, and metal structures by preventing material fatigue and surface wear.

Slows down natural aging and degradation of surfaces exposed to heat, UV, water, or chemicals over time.

Helps retain structural strength and mechanical performance, even in challenging operating conditions.

Minimizes the frequency of replacements, extending capital equipment investment cycles.

3. Reduced Maintenance & Downtime

Greatly reduces the need for frequent surface repairs, repainting, or component replacement caused by wear and corrosion.

Minimizes labor costs and maintenance hours required over the product’s lifecycle, lowering operational expenses.

Helps prevent unscheduled shutdowns or failures, especially in continuous process industries.

Supports smooth and uninterrupted operations by improving component durability and surface stability.

4. Better Appearance & Branding

Provides a consistent, smooth, and attractive surface finish that enhances the visual quality of your products or structures.

Available in a wide range of colors, gloss levels, and textures to meet aesthetic or brand design requirements.

Conceals imperfections such as weld discoloration, scratches, or uneven surfaces, resulting in a clean final appearance.

5. Resistance to Chemicals, Heat & Abrasion

Coatings are engineered to withstand contact with strong acids, alkalis, oils, and industrial solvents without breaking down.

Offers excellent resistance to mechanical damage such as scratches, chips, and surface abrasion caused by handling or vibration.

Withstands high operating temperatures, making it suitable for automotive, furnace, or process equipment.

Maintains coating integrity even in high-pressure washdowns, chemical cleaning, or aggressive service conditions.

WHY PROTECTIVE COATINGS?

Protecting Surfaces. Extending Lifespan. Reducing Cost.

What Are Protective Coatings?

Protective coatings are engineered surface layers applied to metals and other materials to prevent corrosion, enhance durability, and improve appearance in tough working conditions.

Why Choose Us?

In-house blasting + coating with controlled quality

Coatings compliant with ISO 12944, 8501,

Small to high-volume job work capacity

Timely delivery for urgent & project-based requirements

Trained team for process & testing

Tailored to your material, environment & life cycle

Trusted by Our Valued Project & Clients for Superior Protective Coating

Trusted by Our Valued Project & Clients for Superior Protective Coating