Welcome to,

Blast Top, Protecting Your Assets.

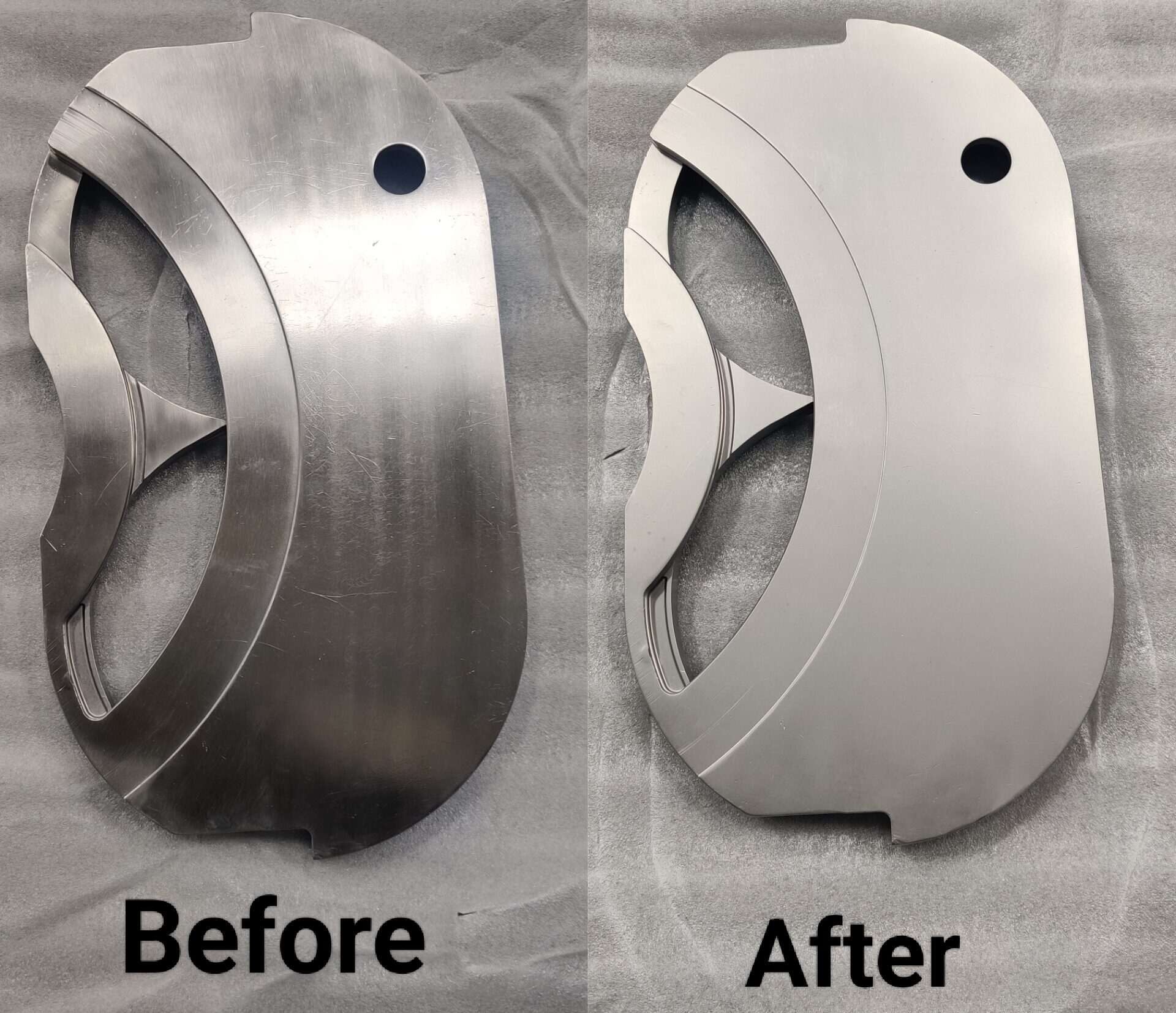

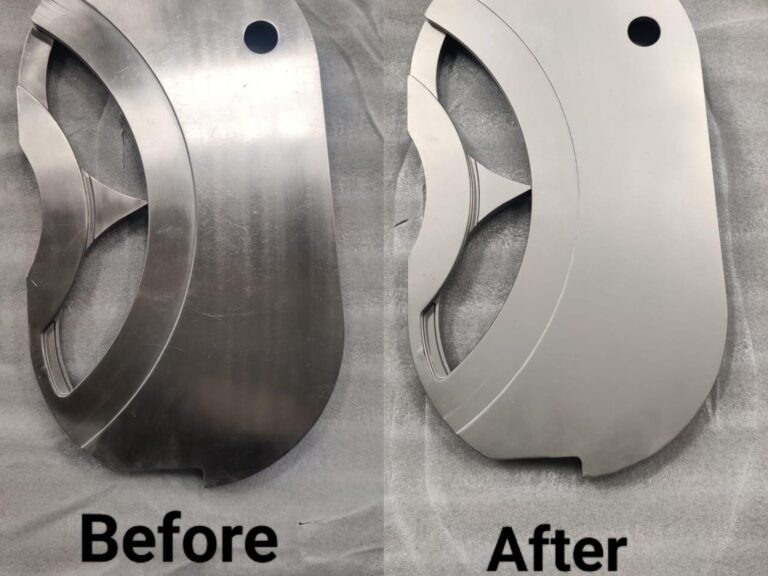

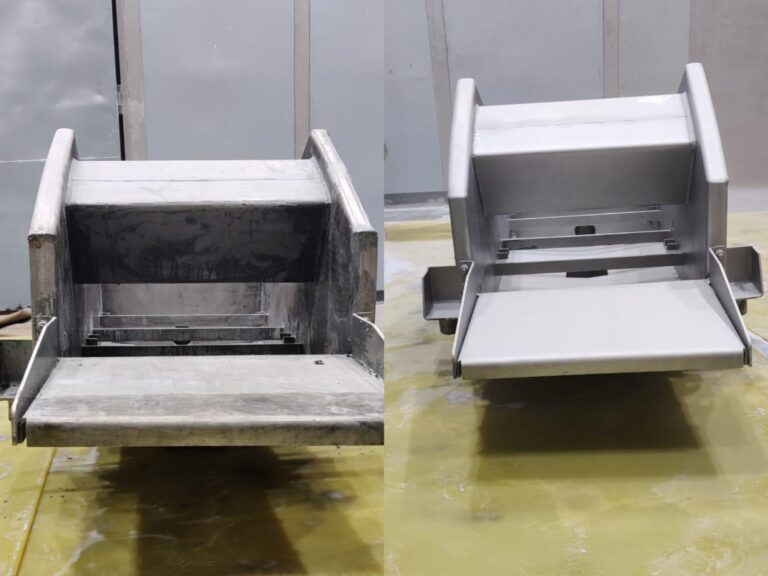

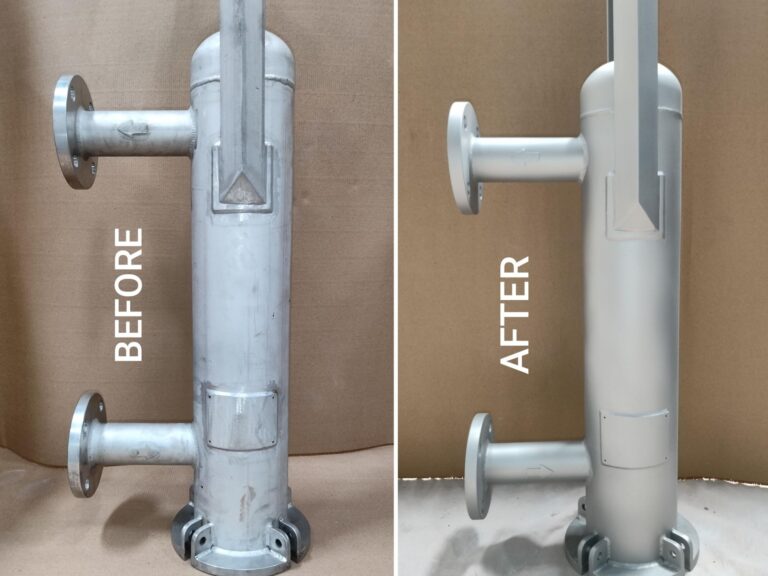

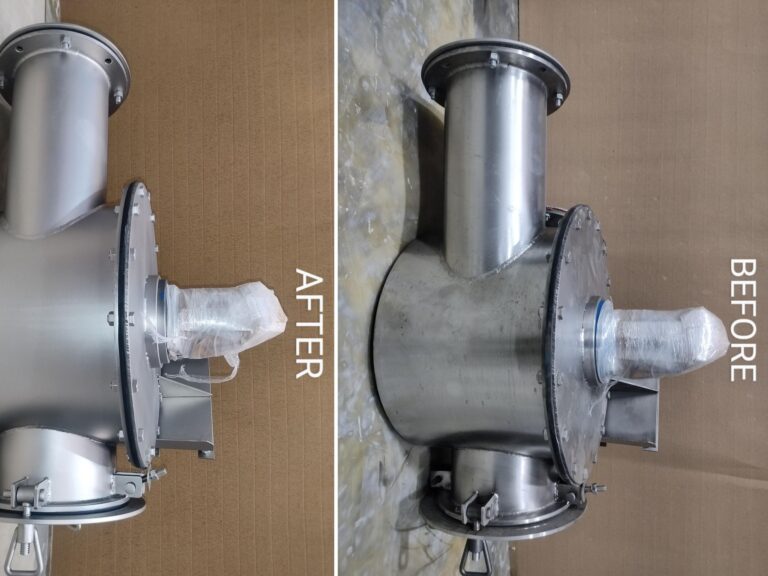

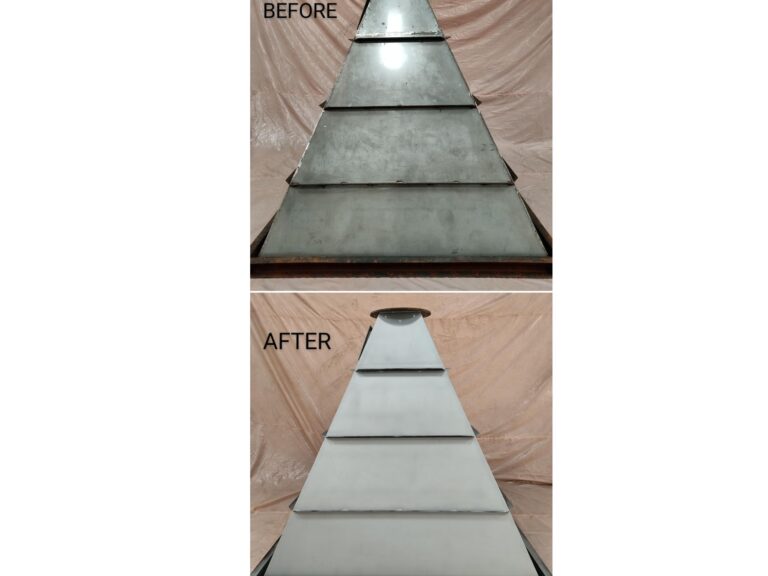

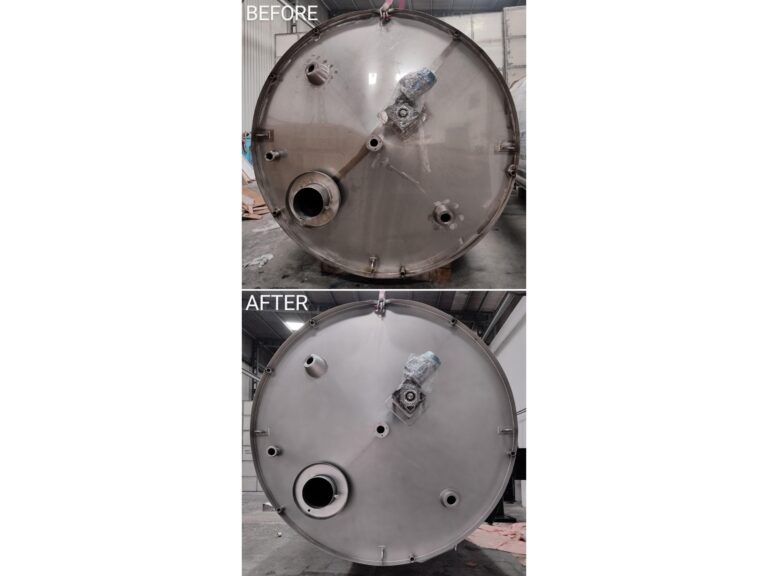

Stainless Steel Surface Finishing

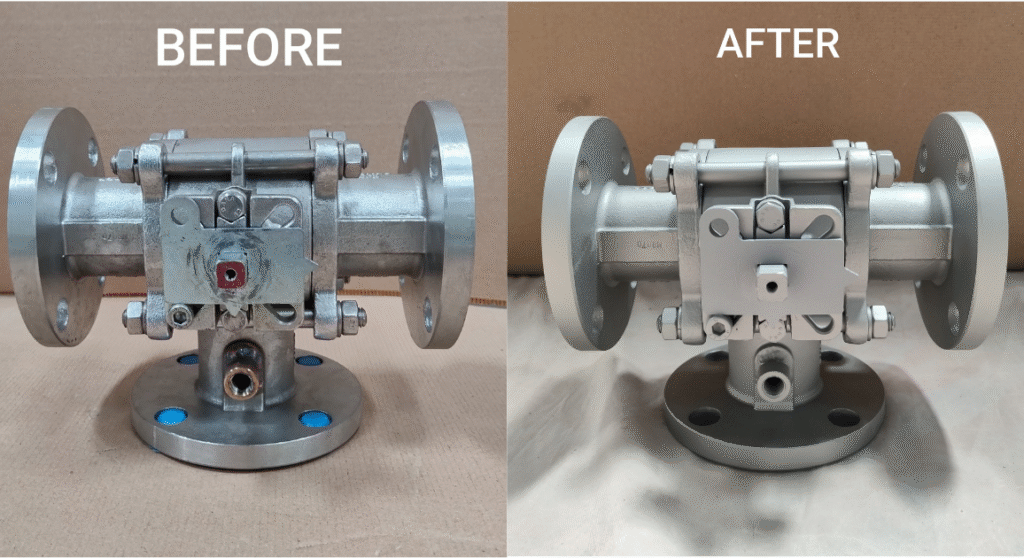

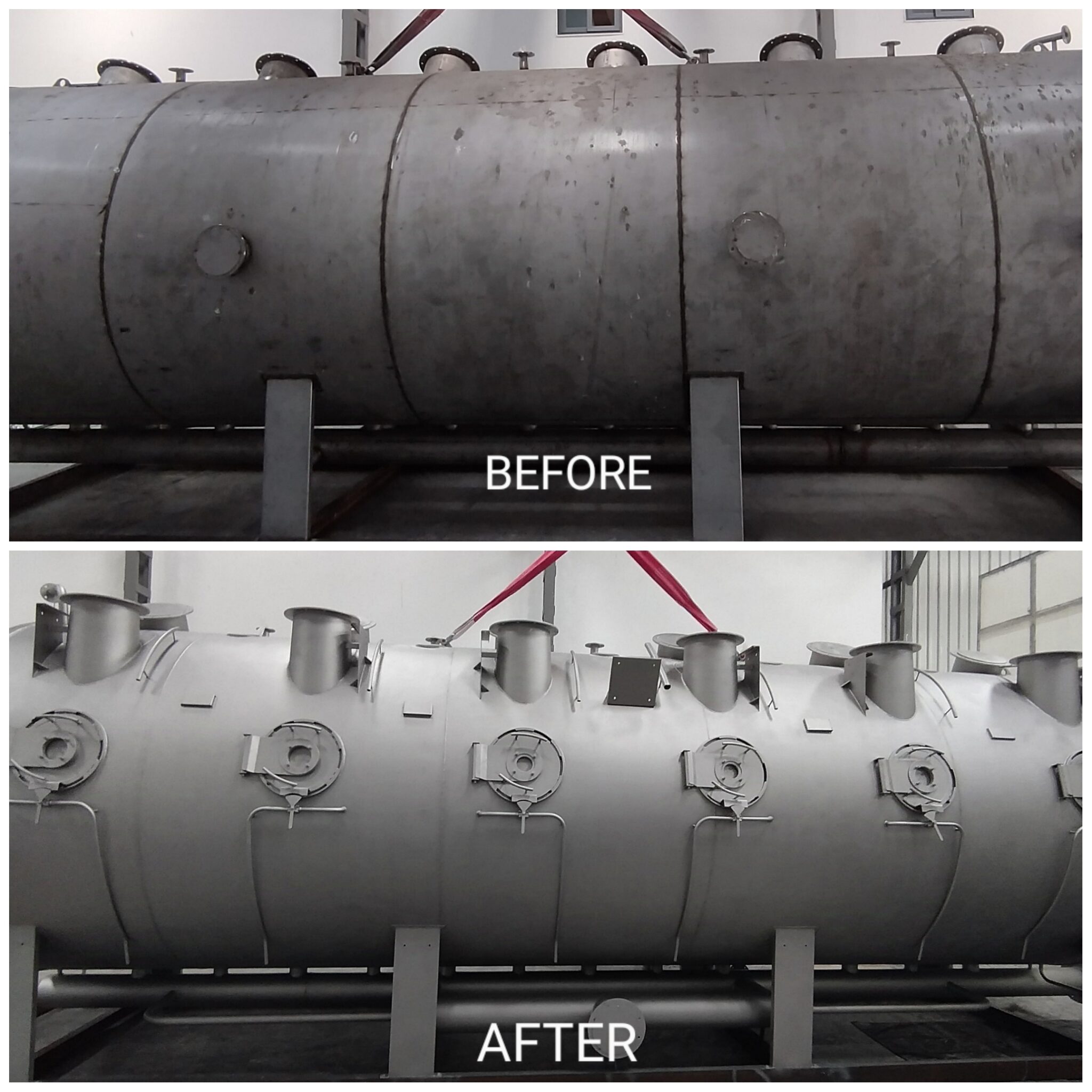

Blast Top helps build brand value with use of Advanced mechanical Surface Finishing Techniques For Stainless Steel and Other Non Ferrous Equipment’s and Machinery .”

Welcome to,

Blast Top, Protecting Your Assets.

Stainless Steel Surface Finishing

Blast Top helps build brand value with use of Advanced mechanical Surface Finishing Techniques For Stainless Steel and Other Non Ferrous Equipment’s and Machinery

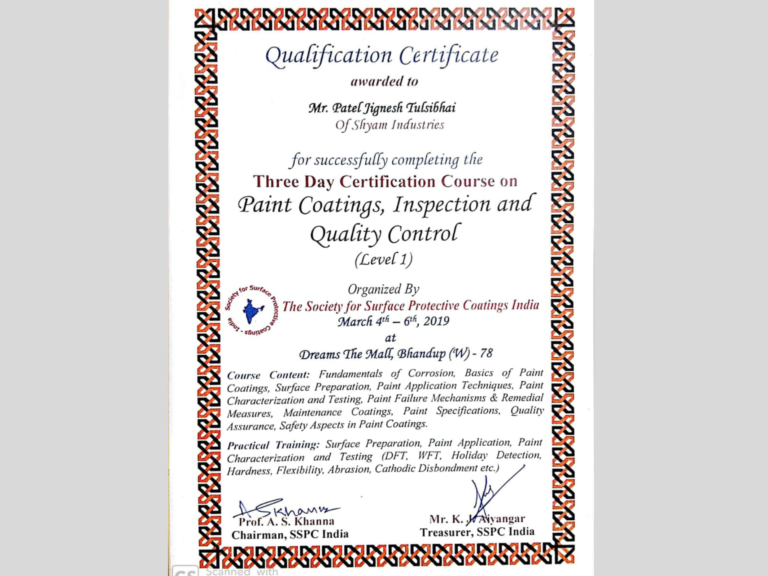

“Blast Top has NACE/SSPC Level 1 & 2 Certified and a highly Experienced professionals Team, which specializes in Stainless Steel and Other Non Ferrous Surface Finishing to deliver top-quality results.”

“Blast Top has NACE/SSPC Level 1 & 2 Certified and a highly Experienced professionals Team, which specializes in Stainless Steel and Other Non Ferrous Surface Finishing to deliver top-quality results.”

Our Applications

- Aircraft Manufacturers

- Airport

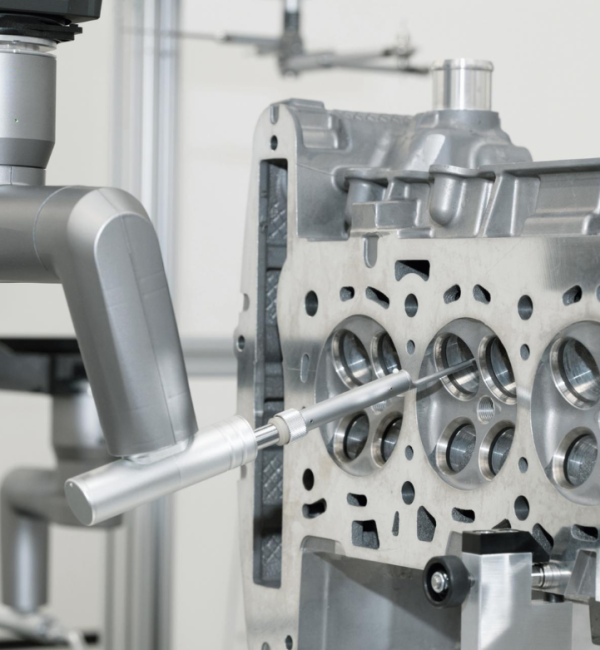

- Automobile Industries

- Auto-Truck Body Builders

- Chemical Plant

- Drug & Pharma Industries

- Food & Dairy Industries

- Holloware Industries

- Pharma machinery Mfg

- Jet Turbine Blade

- Manufacturers

- Machine shop & Engineering

- Plastic machinery

- manufacturers

- Power Station

- Pulp & Paper Mill

- Rubber Plant

- Stamping Plants

- Ship Building

- Surface Cleaning

What We Offer

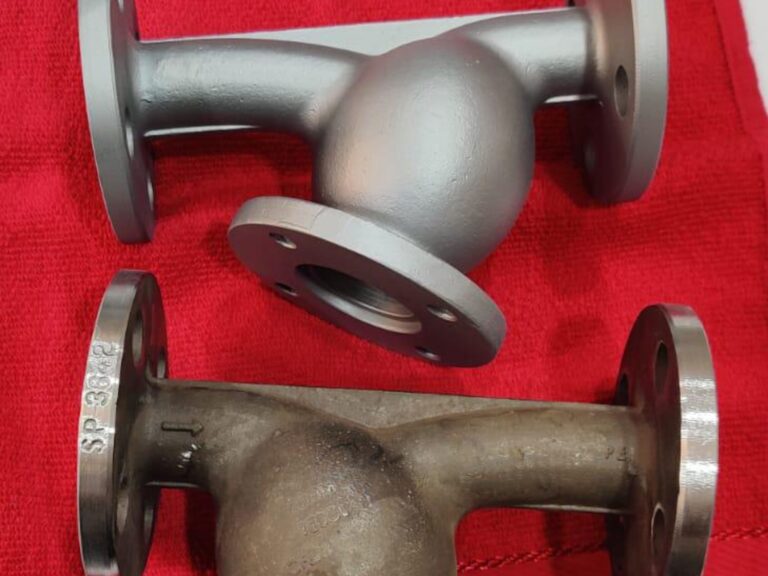

Expert Surface Finishing for Stainless Steel & Non-Ferrous Metals

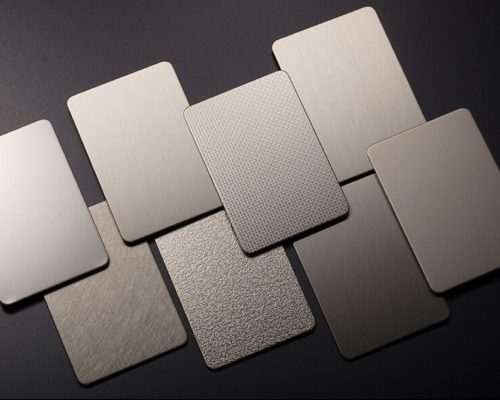

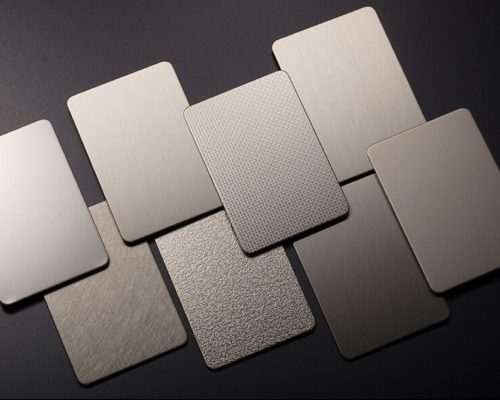

Glass Bead Finishing solutions, a specialized surface treatment used to achieve a uniform, support hygiene cleanability, Non- reflective, Matt, Satin, Semi Gloss, textured Surface Finish. it’s Process ferrite free, and it is removing embedded contaminations, passive corrosion layer, weld discoloration, machining mark on the surface and that enhances both the appearance and durability of metal components.”

Glass Top Finish

Buff Bead Top Finish

Bead Top Finish

Glass Bead Finish

Peen Top Finish

Buffing & Advance Polishing

We are able to deal in high Volume Components For Quick on time delivery.

Blast Top offers a wide range of stainless steel surface finishing services, delivered efficiently by our expert team to ensure fast and

on-time completion.

- Glass Top Finishing

- Bead Top Finishing

- Peen Top Finishing

- Buff Bead Top Finishing

- Glass Bead Finishing

- Buffing & Advance Polishing

Blast Top Finish Is Mainly use In Dairy Machinery, Food Processing, Packaging, kitchen Equipment, Aerospace and Automotive parts, Medical And Surgical Industries Machinery and parts.

- Aerospace and Automotive Parts: Strengthening metal surfaces, cleaning engine components, and restoring aluminum or steel parts.

- Medical and Surgical Instruments: Achieving smooth, contaminant-free surfaces for high-precision instruments.

- Mold Cleaning: Removing residues without damaging mold surfaces used in manufacturing.

- Antique Restoration: Cleaning and restoring vintage metal items while preserving their original structure and detailing.

Overall, Blast Top finishes provides an attractive appearance, durability, and functional surface improvements, particularly for parts requiring precision, cleanliness, and non-aggressive surface treatment.

Blast Top Helps to build your Brand Value

By Export Quality

& attractive look of Stainless Steel Surface Finish.

STAINLESS STEEL SURFACE FINISHING

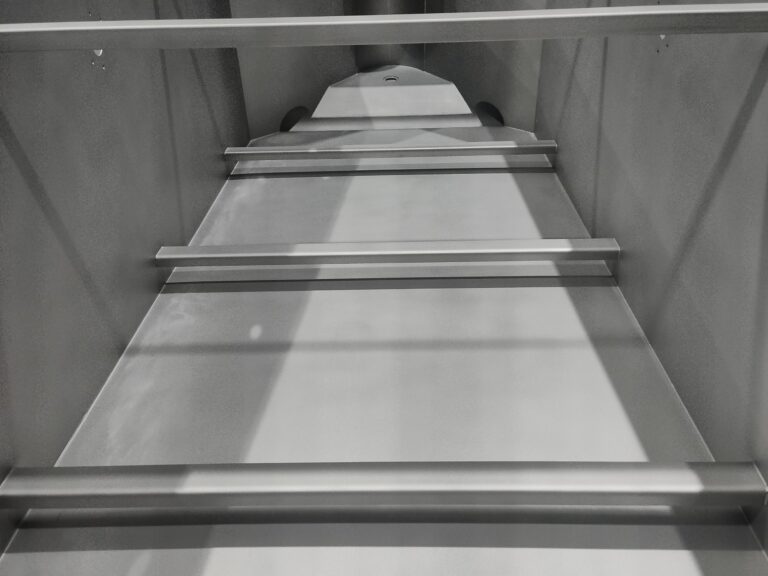

Blast Top Are Able to a Comprehensive Mechanical Surface Treatments & Finishing through Advance Polishing, Glass Bead Finish, Ceramic Bead, Steel Shot, to The Stainless Steel Fabrication & Food, Dairy, Pharma, Machinery Manufacturing Industries.

Blast Top has Number of Surface Finishing Facilities. With dedicated Equipment for Glass Bead Finishing of stainless steel & Other Non-Ferrous Steel.

Our one Facility is Dedicated to Non -Ferrous -stainless steel, Brass, Aluminium, Copper and is kept separate from The Ferrous Facility so no Cross Contamination of components is made.

Office Phone

+91 9054353580

PRECISION. PROTECTION. PERFECTION – BENEFITS OF BLAST TOP FINISH

1. Smooth and Satin Finish

- Aesthetic Appeal: Glass beads create a smooth, uniform, and aesthetically pleasing satin or matte finish on metal surfaces, making it ideal for decorative applications.

- Non-Abrasive: Glass bead Finish is less aggressive than other forms of abrasive. It doesn’t remove significant amounts of material, preserving the dimensional integrity of parts.

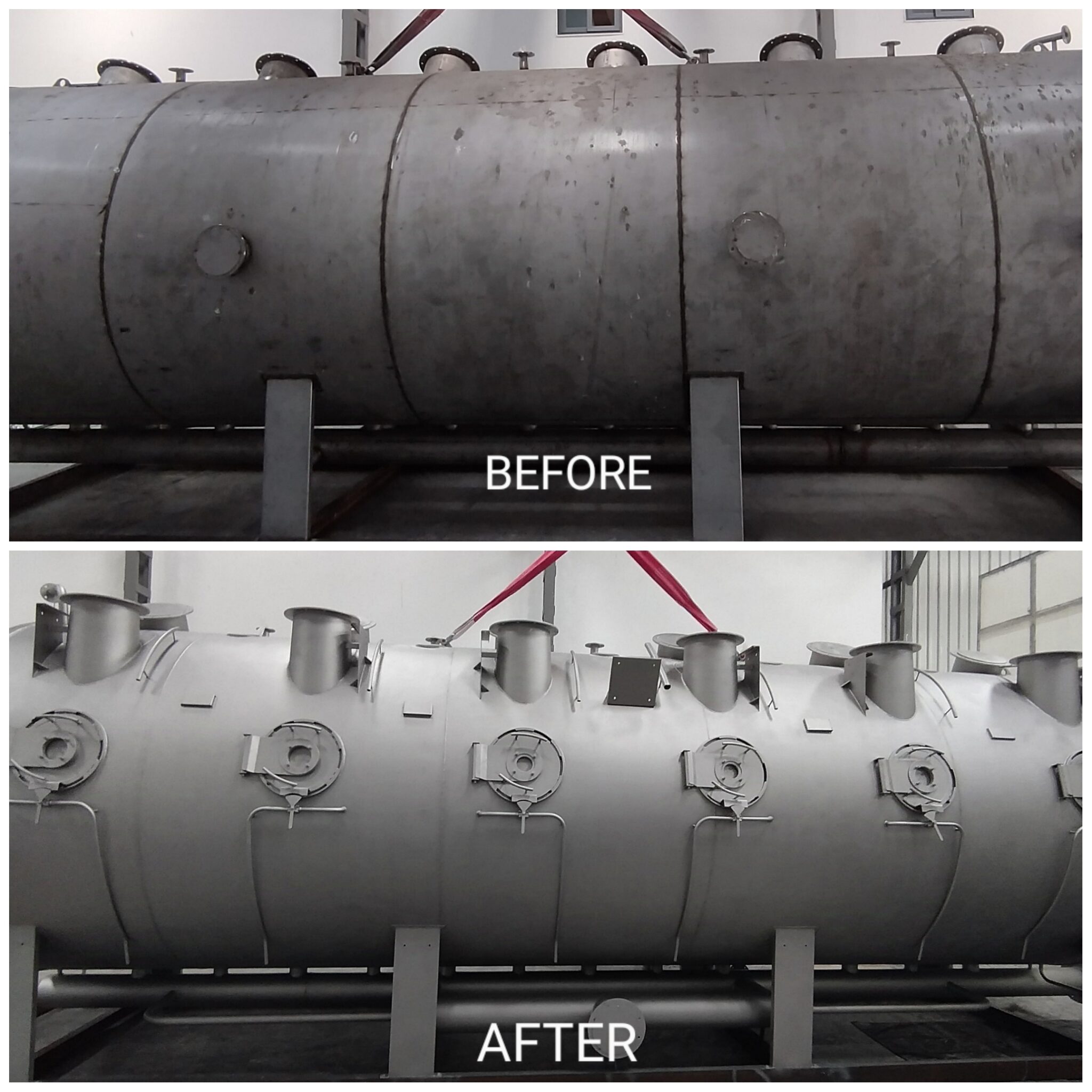

2. Surface Cleaning

- Gentle Cleaning: Glass beads effectively clean surfaces without etching, pitting, or damaging the substrate. They remove dirt, rust, scale, and old coatings from parts while maintaining the surface structure.

- Environmentally Safe: Glass beads are chemically inert and non-toxic, so the process is environmentally friendly and safe for operators when proper safety measures are followed.

3. Peening for Strength

- Surface Peening: Glass bead Finish stimulates surface compression (peening), which increases the metal’s fatigue strength and resistance to cracking and corrosion. This is particularly beneficial for components exposed to cyclical stress, like Dairy, Food, Pharma machinery ,automotive, Defence, or aerospace parts Etc.

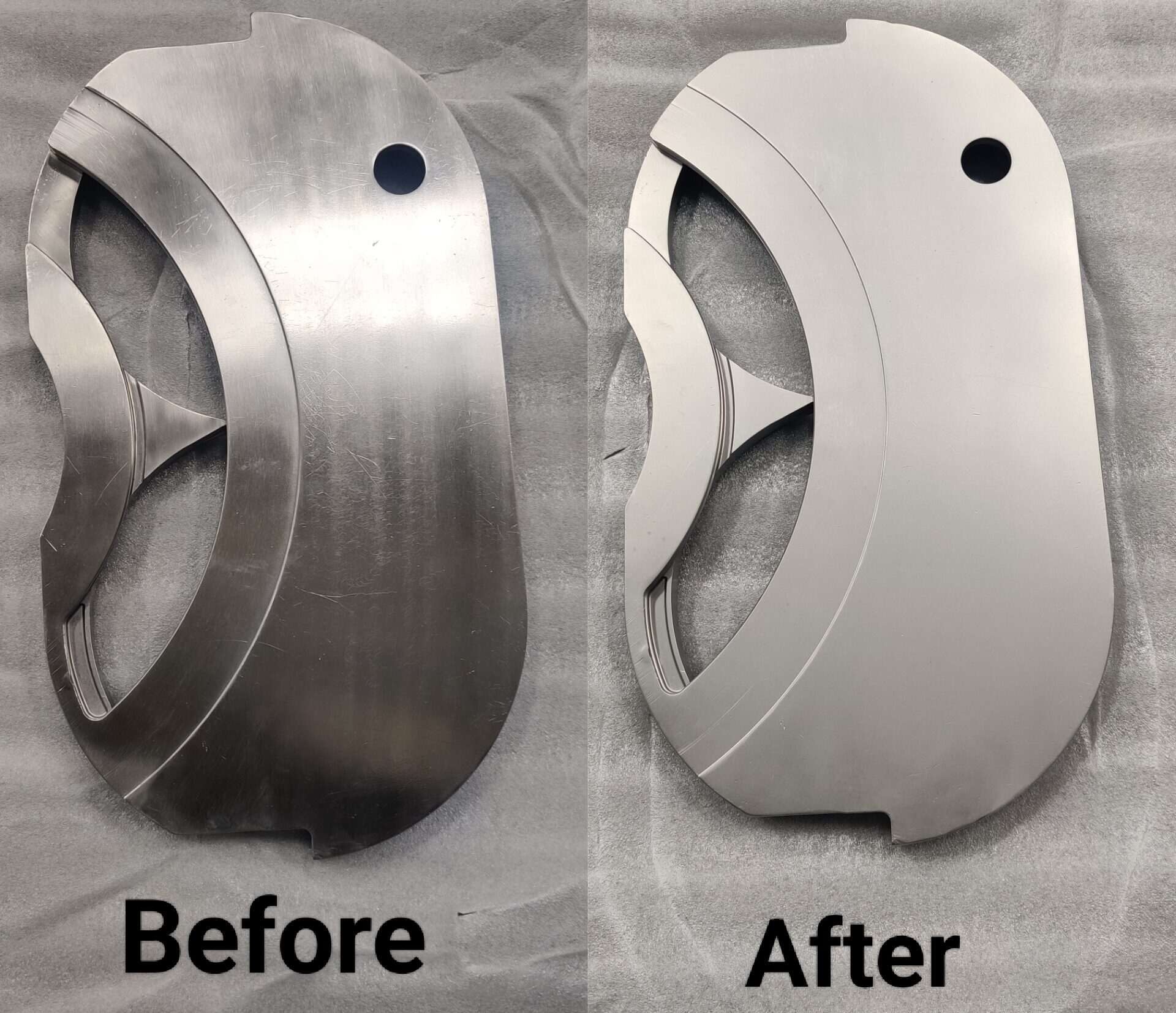

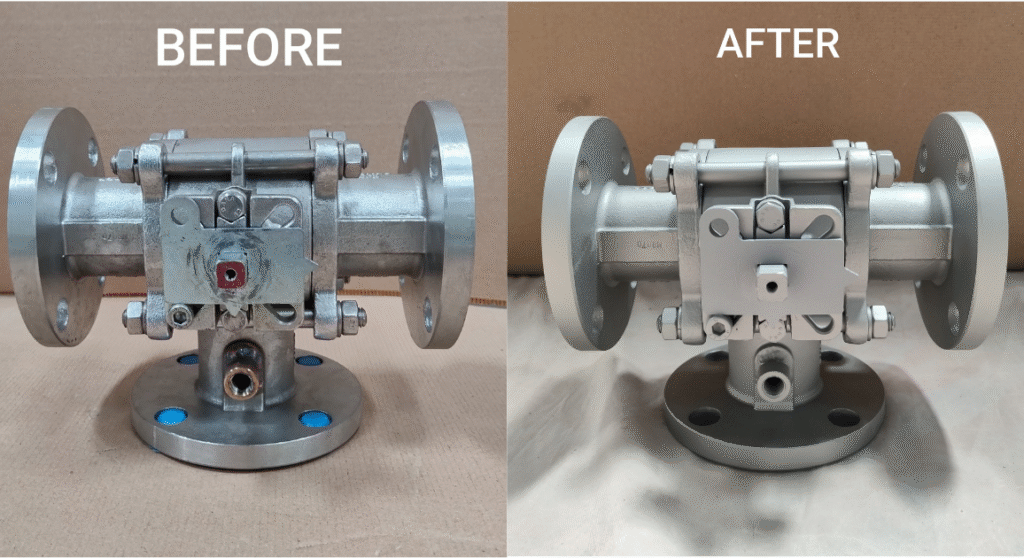

4. Restoration of Parts

- Deburring and Smoothing: Glass beads remove burrs, sharp edges, and imperfections from machined parts without damaging them, making the process excellent for delicate components that need a smooth finish.

- Restoration of Metal Parts: It can restore metal parts (both ferrous and non-ferrous) to their original shine and smoothness, making it great for refurbishing used parts or antique metal objects.

5. Non-Contaminating

- Preserves Material Integrity: Since glass beads are softer than other abrasives like aluminum oxide, they don’t embed in the surface or contaminate the metal, making it ideal for parts that require cleanliness or a smooth surface after Finishing.

- No Surface Etching: Glass bead Finish doesn’t etch the surface like more aggressive media (e.g., aluminum oxide), which is crucial when preparing surfaces that should remain smooth or polished.

6. Corrosion Resistance Enhancement

- Prepares Surfaces for nano Coatings: Glass bead Finish creates a uniform surface that can enhance adhesion for Nano protective coatings, indirectly contributing to corrosion resistance.

Our Glass Bead Finish Name & Typical Applications:

Why Choose Us

Stainless Steel Surface Finishing ?

• End-to-End Facility – In-house Surface Finishing & Treatment with controlled quality.

• Expertise in ISO Standards – Surface Finishing & Coating compliant with ISO Standard.

• Batch Flexibility – Small to high-volume job work capacity.

• Quick Turnaround – Timely delivery for urgent & project-based requirements.

• Certified Technicians – Trained team for process & testing.

• Customized Surface Finishing Systems – Tailored to your material & application.

Our Applications

- Aircraft Manufacturers

- Airport

- Automobile Industries

- Auto-Truck Body Builders

- Chemical Plant

- Drug & Pharma Industries

- Food & Dairy Industries

- Holloware Industries

- Pharma machinery Mfg

- Jet Turbine Blade

- Manufacturers

- Machine shop & Engineering

- Plastic machinery

- manufacturers

- Power Station

- Pulp & Paper Mill

- Rubber Plant

- Stamping Plants

- Ship Building

- Surface Cleaning

What We Offer

Expert Surface Finishing for Stainless Steel & Non-Ferrous Metals

Glass Bead Finishing is a ferrite-free process that removes contaminants, corrosion, and weld marks for enhanced durability. It provides a uniform, hygienic surface with matte to semi-gloss textured finishes.

Glass Top Finish

Buff Bead Top Finish

Bead Top Finish

Glass Bead Finish

Peen Top Finish

Buffing & Advance Polishing

We are able to deal in high Volume Components For Quick on time delivery.

Blast Top provides expert stainless steel surface finishing with fast, on-time delivery and reliable service.

- Glass Top Finishing

- Bead Top Finishing

- Peen Top Finishing

- Buff Bead Top Finishing

- Glass Bead Finishing

- Buffing & Advance Polishing

Blast Top finishes are used in dairy, food, kitchen, aerospace, automotive, and medical industries for precise, clean, and durable surface treatment. Ideal for engine parts, surgical tools, mold cleaning, and antique restoration, they offer both functional and aesthetic enhancement.

Blast Top Helps to build your Brand Value

By Export Quality

& attractive look of Stainless Steel Surface Finish.

STAINLESS STEEL SURFACE FINISHING

Blast Top offers advanced polishing and blasting for stainless steel and non-ferrous metals like brass, aluminum, and copper. We serve food, dairy, pharma, and machinery sectors with separate facilities to prevent cross-contamination.

Contact Us

+91 9054353580

PRECISION. PROTECTION. PERFECTION – BENEFITS OF BLAST TOP FINISH

1. Smooth and Satin Finish

- Aesthetic Appeal:

Glass bead finishing gives a smooth, uniform, matte look—ideal for decorative and aesthetic applications.

- Non-Abrasive:

It’s a gentle process that preserves part dimensions without removing significant material.

2. Surface Cleaning

- Gentle Cleaning:

Cleans surfaces effectively without etching or damaging, removing rust, scale, and coatings safely.

- Environmentally Safe:

Glass beads are non-toxic and inert, making the process safe for both the environment and operators.

3. Peening for Strength

- Surface Peening:

Improves fatigue strength and crack resistance—perfect for parts in dairy, food, pharma, automotive, and aerospace sectors.

4. Restoration of Parts

- Deburring and Smoothing:

Smooths and deburrs delicate parts without damage, ensuring clean, finished edges.

- Restoration of Metal Parts:

Restores shine and smoothness to used or antique metal parts, both ferrous and non-ferrous.

5. Non-Contaminating

- Preserves Material Integrity:

Softer than other abrasives, glass beads avoid contamination or surface embedding.

- No Surface Etching:

Doesn’t etch like harsher media—maintains a smooth or polished surface finish.

6. Corrosion Resistance Enhancement

- Prepares Surfaces for Nano Coatings:

Creates a uniform base for nano coatings, enhancing adhesion and corrosion resistance.

Our Glass Bead Finish Name & Typical Applications:

Why Choose Us

Stainless Steel Surface Finishing ?

In-house surface finishing with quality control

ISO-compliant processes

Flexible batch sizes

Fast turnaround

Certified, skilled technicians

Custom finishes for specific materials and needs

Trusted by Our Valued Project & Clients for Superior Stainless Steel Surface Finishing.

Trusted by Our Valued Project & Clients for Superior Stainless Steel Surface Finishing.